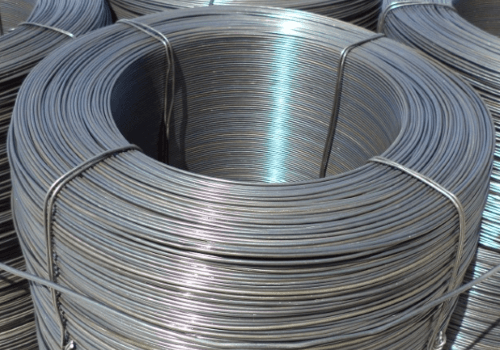

Top quality black annealed wire, softened through an heating treatment (annealing process), increasing the ductility and improving it’s workability.

Easy to handle, they can be used in agriculture (straw tying), construction (tying wire) and industry (baling wire).

| % C | % Mn | % Si | % P | % S | Standard |

| ≤ 0.13 | ≤ 0.60 | ≤ 0.30 | ≤ 0.035 | ≤ 0.035 | ISO 16120 |

| ≤ 0.13 | ≤ 0.60 | ≤ 0.30 | ≤ 0.040 | ≤ 0.050 | ASTM A510 |

| Diameters (mm) | Rm (MPa) | A50mm (%) | Diameter Tolerance |

|---|---|---|---|

| 1.50 to 3.00 | 300 to 450 | 30 to 40 | ± 0.06 |

| > 3.00 to 3.90 | 300 to 450 | 30 to 40 | ± 0.07 |

| Surface Finishing | Application | Anti-rust protection | Packaging |

|---|---|---|---|

| Black Annealed | Automatic baling units: recycling papers, cardboard, plastics cereals and others. | Oiled or Dry | Wire tying. On pallet, with plastic foil and cardboard on top / bottom. Another packaging solution could be adopted, according with the client specification. |

| Diameter (mm) | Coils Dimensions (mm) | Weight (kg) | Unwound direction | ||

|---|---|---|---|---|---|

| Ø Internal | Ø External | Height | |||

| 1.50 to 3.00 | 180 | 260 to 320 | 160 | 25 to 54 | Optional |

| 200 | |||||

| > 3.00 to 3.90 | 180 | 260 to 320 | 160 | 25 to 54 | Optional |

| 200 | |||||

Other specifications on request.